- ****Plan accordingly to receive items when you need them. ALL "Made to Order" items with lead times will effect the entire order fulfillment timeline. Custom items are NOT mass produced and require fabrication time. Orders will ONLY ship out in their entirety. If you need standard items shipped sooner, place multiple orders.****

- .

MADE IN THE U.S.A!!

For best Customization and Fit, Three Replacement Rod Lengths are available:

4.125"

4.25"

4.375" OEM Length

UPDATE 3/23/2018: We have developed an add-on to our Die to work with custom toolheads with 7/8-14 threaded holes above priming station. Perform the same steps and select from the drop down menu the thread I.D. to the nearest 0.001" and we will do the rest. Use a reliable set of calipers, measure at least 2 cross sections on the top and bottom of the toolhead. Use the smallest measurement for die selection.

Install Video and Pictures Below

PATENT PENDING

*Use Support Rod’s beveled tip for bottle neck casings and the blunt end on wide mouth casings.*

Accepts casings within the following sizes:

Up to 30-06 Case Length

Up to 45 ACP Case Width

22 Caliber Case Mouth Opening or bigger

UPDATE(1/8/2018)- Made from a combination of 6000 and 7000 series Aluminum to ADD additional Strength and Quality!

UPDATE EFFECTIVE 6/28/2017

We have changed USA Spring manufacturers. The "OLD" Springs are NOT obsolete. Purchases ON or AFTER 6/28/2017 will use the "NEW" Spring.

EACH DIE IS CUSTOM MADE TO FIT EACH SPECIFIC TOOLHEAD (this dimension tends to vary between toolheads)

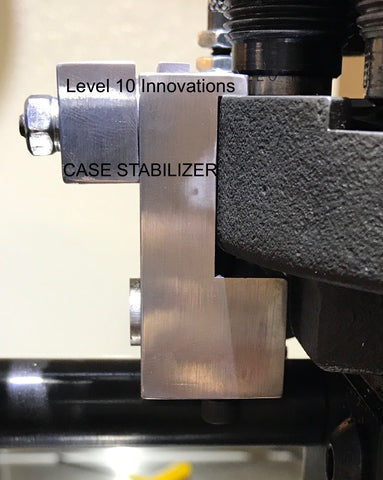

Proprietary Design by Level 10 Innovations

Get yours now!! Intro and Instruction video/pictures below.

Parts:

- Machined from solid 6061-T6 AND 7075-T7 Aluminum. (may contain markings from the fabrication process)

- Industrial Die Spring (we dare you to try and wear it out, set at 0.850"{This is a starting point for Spring Pre-Tension}. Spring only cycles a fraction of an inch with each press cycle...cycles are what wear and break springs)

- Support Rod is hardened for wear resistance

- High quality industrial hardware (as pictured or similar)

Key Features:

- Prevents the brass from tilting which provides a more perpendicular installment of the primer

- Absorbs case web and rim thicknesses without affecting seating depth

- Maintains Casings downward against shellplate

- Zero Flex/Stress on shellplate

- Reliable and Consistent Primer seating depth

- Designed to NOT ignite primers if casing is not present in priming station

- Eliminates having to over seat primers due to flex in shellplate, primer pocket tension etc, which can cause unwanted primer ignition.

- Once installed and setup, easy removal and reinstall without any adjustment...just unscrew the lower assembly/bushing and remove. All presets are maintained in the upper assembly

Once you understand the function of the die faster setup is achievable. Video below depicts failsafe and the ONLY recommended procedure for safe and proper setup, any variation to its procedure is not recommended.

Install Instructions:

The following Original Video is used for Reference Purposes ONLY. The Install instructions above supersede the information in the video.

Disclaimer:

Since we cannot verify the end use and setup of our product, each user assumes complete responsibility for safety to ALL Equipment and/or Person. Level 10 Innovations or its affiliates are not responsible for and damage or injury. All safety precautions during ANY reloading session requires proper safety gear.